What Is Ingress Protection (IP) Testing?

Electrical and electronic devices and equipment must be protected by an enclosure against the ingress of dirt, dust, water, and contact with body parts or objects, depending on the place of use and ambient conditions. This serves to prevent danger to persons and to ensure the function of the device by preventing failures caused by water, corrosion or conductive contamination. In addition, mechanical stress, for example from impacts, must be avoided to ensure reliable use.

Categorisations to Determine the Ingress Protection of an Electrical Device

- IEC 60529 / EN 60529 is the international standard that defines the IP Code for classifying protection against dust and water.

- ISO 20653 is another international standard focused on Road vehicles, it is harmonized with IP Code following the same classification but it also specifies the testing requirement according to the type of vehicle (passenger cars, motor buses, tractors, motorcycles, etc).

- IEC 60598 is a specific standard for IP on luminaires, with specific classifications and test requirements.

- NEMA 250 ingress protection is mainly used in the United States and Canada for electrical equipment rated at 1000 Volts or less, intended to be installed and used in ordinary and hazardous locations.

- There are also specific military standards, such as MIL-STD-810, MIL-STD-202, MIL-STD-750, and MIL-STD-883, which reference different ingress protection requirements for military applications.

- The aerospace standard RTCA-DO-160 also has a waterproofness section.

Those classifications are similar but not interchangeable, nor the severity of the tests. Military standards are much harsher, but some commercial manufacturers may choose to comply with military-grade standards to highlight the protection level of its product.

International IP Code Classification

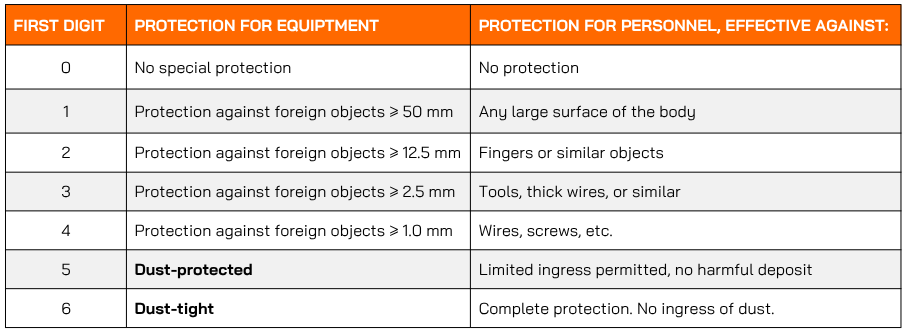

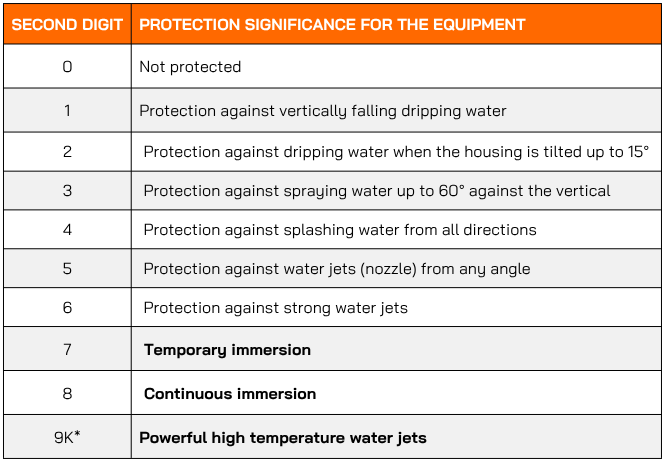

The IP Code ratings system has two digits. The first digit ranges from 0 to 6, it is the ingress protection against solid bodies. The second digit ranges from 0 to 9, it is the ingress protection against liquids. The two digits are completely independent of each other.

Some devices only need to be IP rated to one of the two digits. If a product is only tested to liquid and not solids, it can have an “X” for the solids digit. This is why the testing is sometimes called IPX testing. Given these parameters, there are 70 combinations of ingress protection codes.

There is an optional third letter that refers to when using high pressure.

First Digit of the IP Code: Protection Against Solid Particle, Sand and Dust Testing

Testing for solid foreign objects ingress protection include fingers and other objects but also sand and dust. For larger objects, IP testing facilities use calibrated probes to check for case openings.

In IP dust testing, the item is placed in a sealed chamber where calibrated dust is continuously agitated and blown around the enclosure After testing, the enclosure is cleaned and opened to inspect for internal dust.

Second Digit of the IP Code: Protection Against Water

Many products, such as car headlights, cell connectors, and various electronic components, must function reliably, especially when used in humid environments or outdoors. Resistance to splash water is therefore an important quality feature that is tested in our laboratory to evaluate the resilience of electrical devices and components. Our laboratory is designed for IP protection classes IPX1 to IPX9k, which indicate protection against water ingress with damaging effects.

* Identified as IPX9 in standard IEC 60529. All tests with the letter ‘K’ are defined by standard ISO 20653

Why Choose Applus+ Laboratories Ingress Protection in Europe and North America?

At Applus+ Laboratories, we have a global network of laboratories capable of providing IP testing services for different standards and with different industry specializations (lighting, automotive, aerospace, military). We can test for all the relevant standards, including NEMA, as our IP test laboratories in the United states and Canada are both certified NEMA 250 testing laboratories with significant expertise in interpreting the NEMA 250 standard.