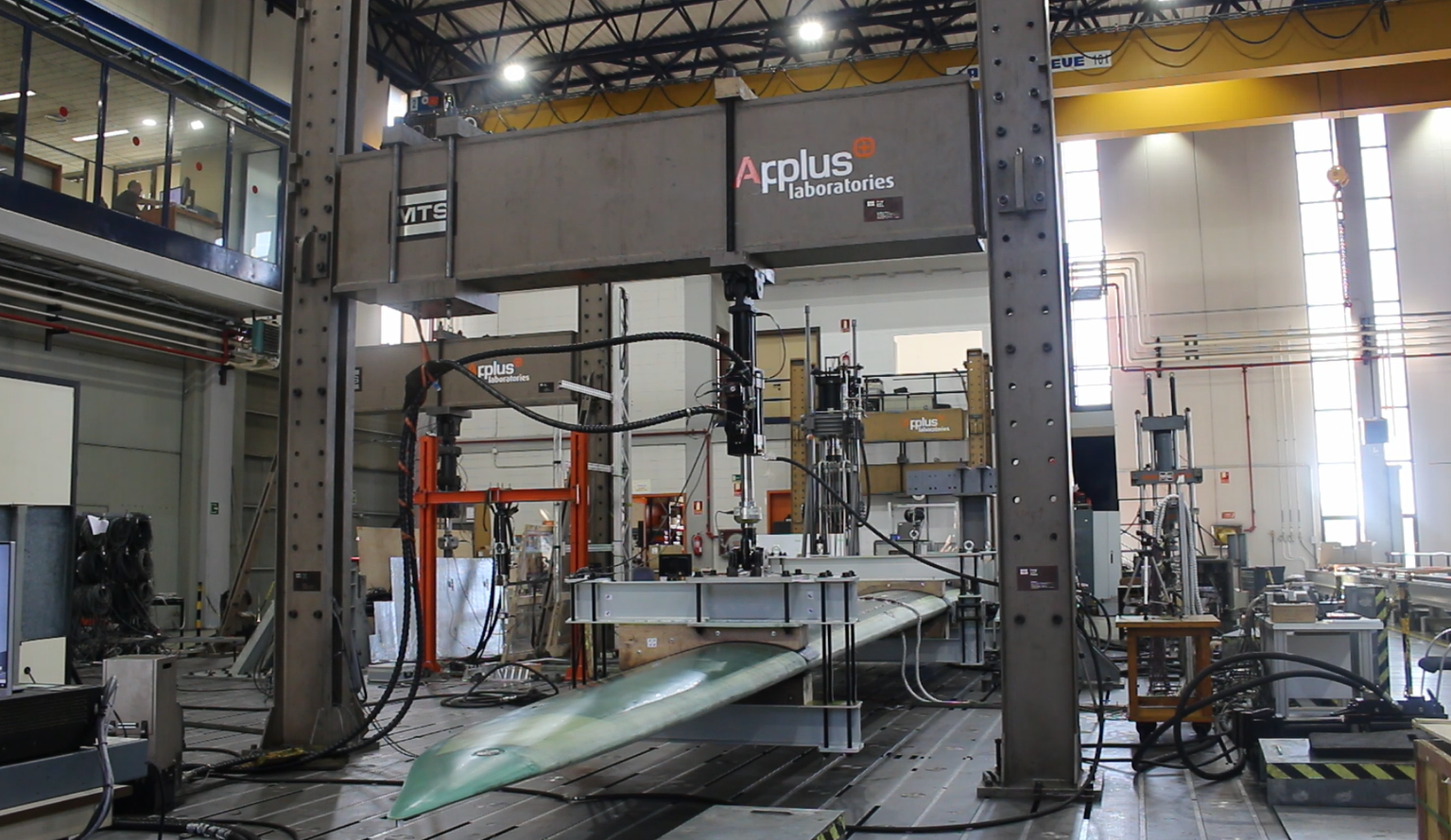

To be approved for use on a wind farm, all the parts of a wind turbine must be tested to ensure they will perform consistently regardless of the mechanical loads and environmental influences they are subject to. The blades must undergo full-scale structural testing for proof of compliance with international safety regulations, like IEC 61400-23. Then, the blades’ subcomponents must also be assessed for their structural integrity, as well as the components making up the rest of the turbine.

Your testing partner for wind turbine structural validation

We perform bespoke test plans to help you optimise your components as well as the set test methods required for certification. We have extensive facilities for performing cyclic and quasi-static rotor blade tests under IEC 61400-23 (complete rotor blades), and use advanced simulation and measuring tools for exceptional precision in our results. What’s more, our project management expertise and in-house test tooling capabilities mean we can meet the tightest of deadlines – both from our Spanish and German facilities.

Our facilities include:

- High-load universal testing machines (up to 15,000 Kn / 3,372 Kips)

- Large and versatile facilities for full scale testing (for cyclic and quasi-static tests under IEC 61400-23) and sub-component testing

- Testing under controlled temperature conditions

- State-of-the-art technology for data acquisition and test monitoring

- Acoustic cameras and advanced metrological equipment

- Damage verification with non-destructive testing equipment

.2022-03-21-17-43-29.png)

Expert quality assurance from the material level up

While our structural testing services assist you in the validation stage, we have a global network of materials testing laboratories to support you all the way from R&D to certification for new turbines. All of our labs are ISO 17025 accredited and we have a huge park of universal testing machines (from 1N to 500Kn) available.

We offer advanced composite material characterization to help you select the best rotor blade materials, as well as metallic material testing and fastener testing.

.2022-03-21-17-44-01.png)

Remote test monitoring to keep you in the loop

Choose Applus+ Laboratories and benefit from our e-Testing platform, designed to keep everyone up to speed, in real-time. Any member of your team can remotely monitor and even participate in the testing and gathering of results, depending on their assigned role.