DIMENSIONAL VERIFICATION SOLUTIONS FOR LAMPS

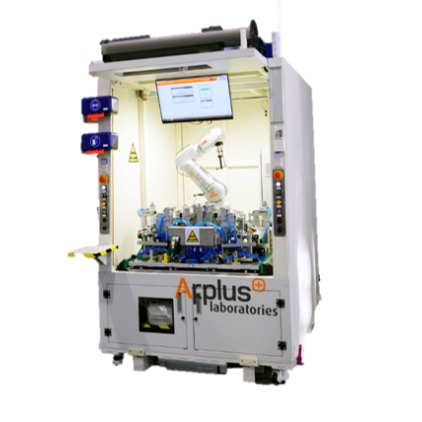

Applus+ has developed a dimensional verification workstation for production lines, with worldwide deployment capacity and present in 4 continents.

Dedicated Tooling Fixed Test Point

Robotic Arm Programable Test Point

Specifications

- Cycle time: Up to 30s for 1 set with 2 lamps

- Repeatability (Cg):

- Flush & Gap 1,67 [±50μm]

- RPS 1,67 [±10μm]

- Traceability records

- Measurement through contact probes. 1μm resolution

- With more than 50 measurement points

- Correlation pattern for adjustments

- One machine can test different designs

- Connectivity to factory data management systems

SOLUTIONS FOR END-OF-LINE FUNCTIONAL TESTS

Applus+ laboratories has developed in-line solutions to perform lamp functional verification. Our equipment is able to test the most common quality

requirements, including:

Electrical and Electronic

Leakage

Lighting operations and patterns

SOLUTIONS TO TEST ALL POSSIBLE LAMP CONFIGURATIONS

Applus+ equipment for production testing has been designed for maximum adaptability. No matter what kind of lamp you produce, it fits our solution. We have experience with head and rear lamps including larger lamps with both left and right sets in the same housing.

Mono head lamps

Mono rear lamps

Dual lamps

Complementary Services

Lighting ECU Validation

Applus+ engineering teams develop tailored functional test benches and hardware-in-the-loop systems (HILs) for lighting Electronic Control Units (ECU) and their integration. We also provide cybersecurity evaluation services for ECU.

Testing services for lamps

- EMC testing (recognized by major OEMs, including Ford, JLR, FCA, GM and Hyundai)

- NVH testing

- Climatic testing with vision monitoring equipment

- Photometry testing

- Materials & mechanical testing

- PCB analysis

- Type Approval