Structural Testing

FROM MATERIALS TO FULL-SCALE TESTING

Applus+ Laboratories is the leading European company for structural testing. Combining the capabilities of our laboratories in Germany and Spain, we support manufacturers in the development and validation of their products. Our testing capabilities cover everything from materials to full-scale tests, to whole aircrafts or railcar bodies. Our expertise encompasses knowledge about advanced materials, such as composite, polymeric, and metallic types.

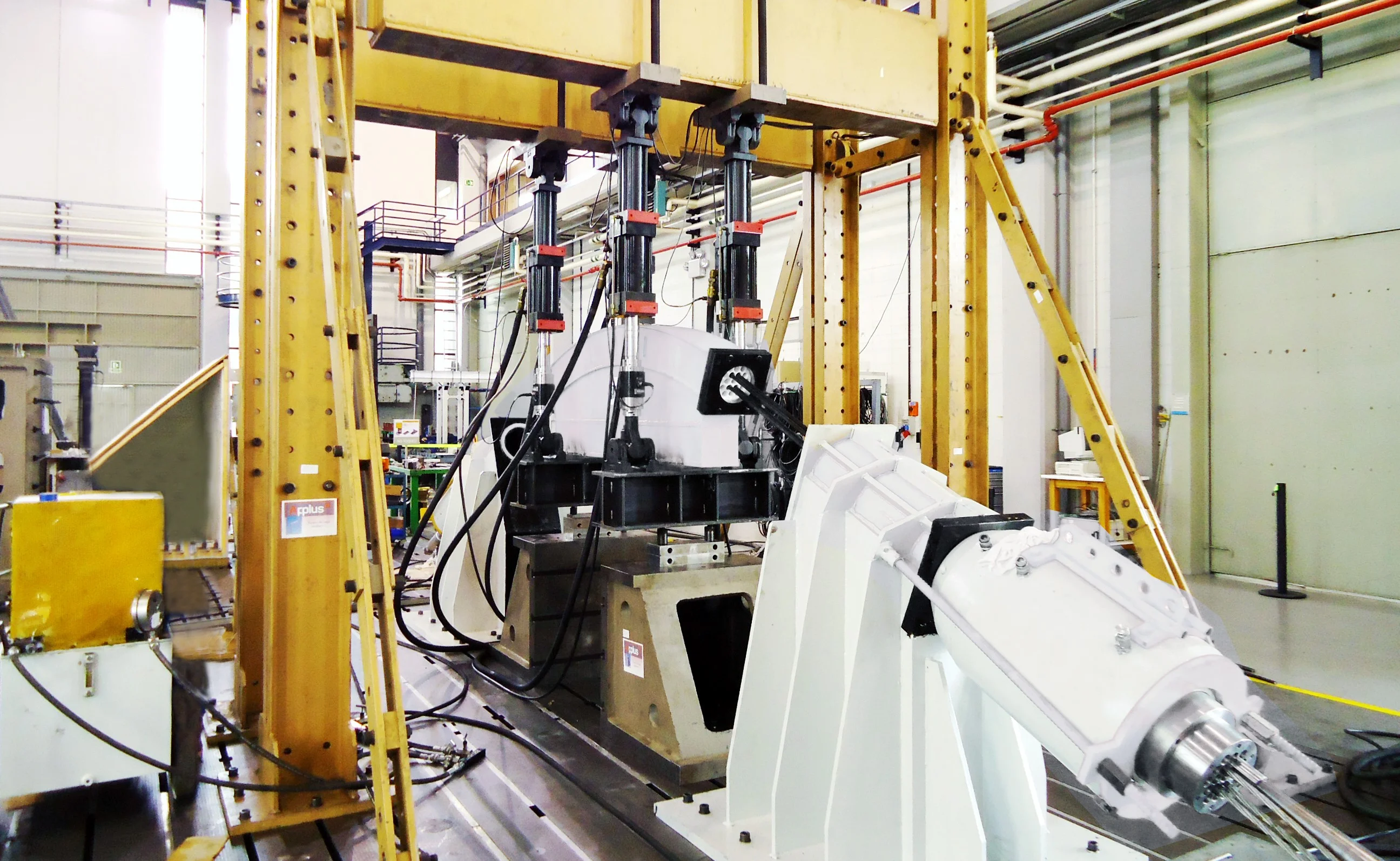

LARGE AND VERSATILE TESTING FACILITIES

- Static and fatigue tests to evaluate strength, durability, and operational stability of components and structures.

- High-load uniaxial testing on small to large components up to 15 MN (flat panels, bridge cables, huge fasteners).

- Multiaxial tests for components with complex loads (curved panels, wind turbine blades, car chassis, or rocket structures).

- Ad-hoc Test Rigs: When the size or the complexity of the tests require ad-hoc solutions, our engineers calculate, design, and manufacture specific test rigs, to be operated in our labs or in our client facilities.

- Testing under controlled thermal conditions, from cryogenic to high temperatures, using advanced data acquisitions and test monitoring systems.

TEST, SIMULATE, COMPUTE, TEST

Our engineers help optimize products both in development and in service, using numerical simulation and strength evaluations.

- FEM Analysis: static, fatigue strength, and dynamic analysis.

- Strength Evaluations: calculate and verify the strength of your designs, combining finite elements and strength tests.

VAST EXPERIENCE TESTING FOR THE MOST DEMANDING INDUSTRIES

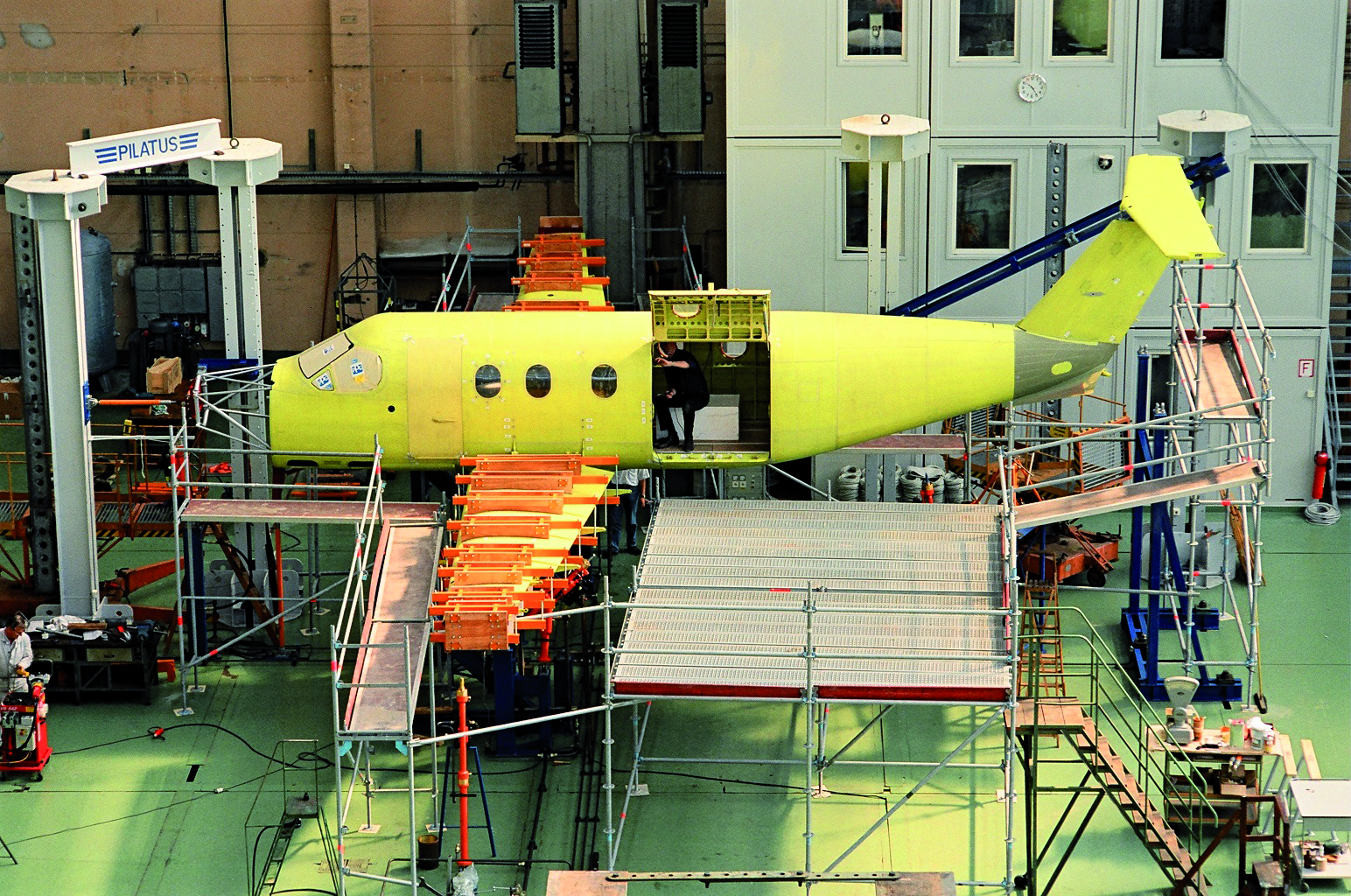

AEROSPACE

Applus+ Laboratories is an approved strategic provider of structural mechanical testing for major aerospace manufacturers. We test all kinds of aircrafts, rotorcrafts, and spacecrafts structures and components.

- Complete aircrafts

- Panel Testing (flat and curved)

- Components

- Engines

- Landing Gears

Our structural testing laboratory upholds strict quality criteria, certified under the aerospace sector’s ISO 9100 standard.

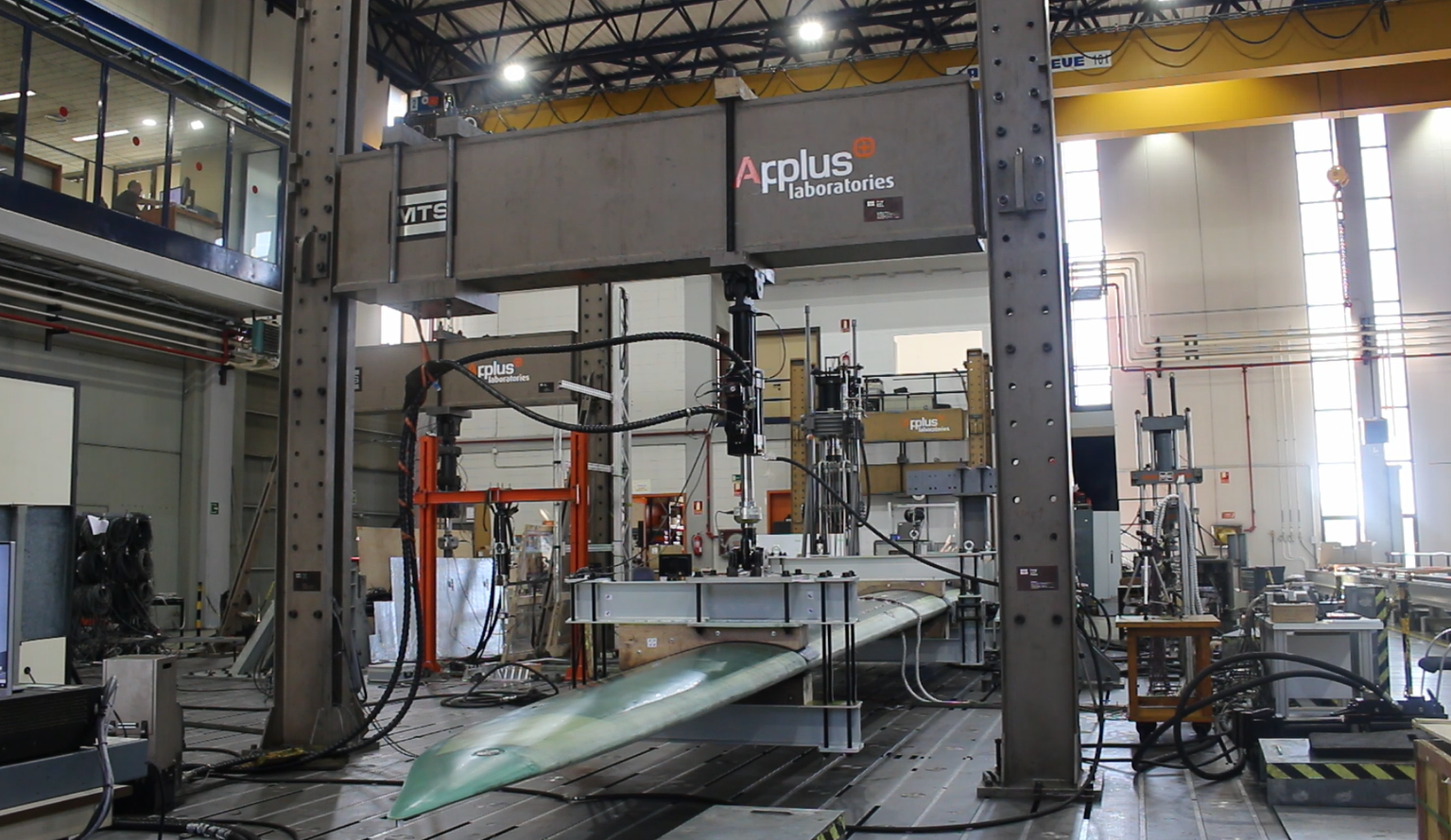

WIND POWER

Our structural lab's partnerships with wind turbine manufacturers allow us to test the mechanical loads and environmental influences on materials, components, and structures.

We perform bespoke test plans to help you optimise your components and set the right testing methods required for certification. We have extensive facilities for performing cyclic and quasi-static rotor blade tests under IEC 61400-23.

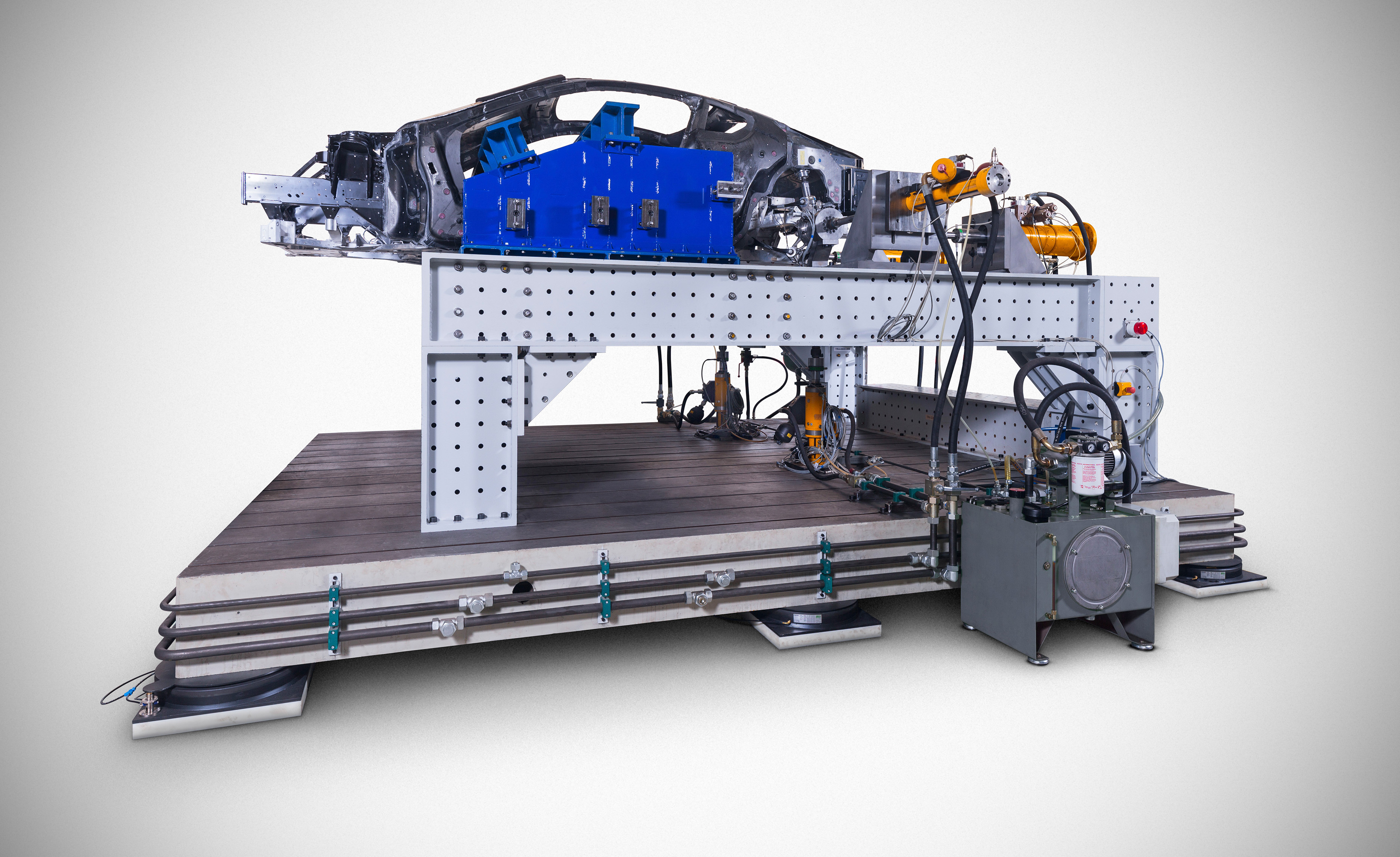

AUTOMOTIVE

Applus+ Laboratories provides stability, reliability, and development testing for automobile components and structures:

- Complete Vehicles and Vehicle Bodies

- Chassis and Chassis Components

- Engines and Engine Components

- Transmission Components

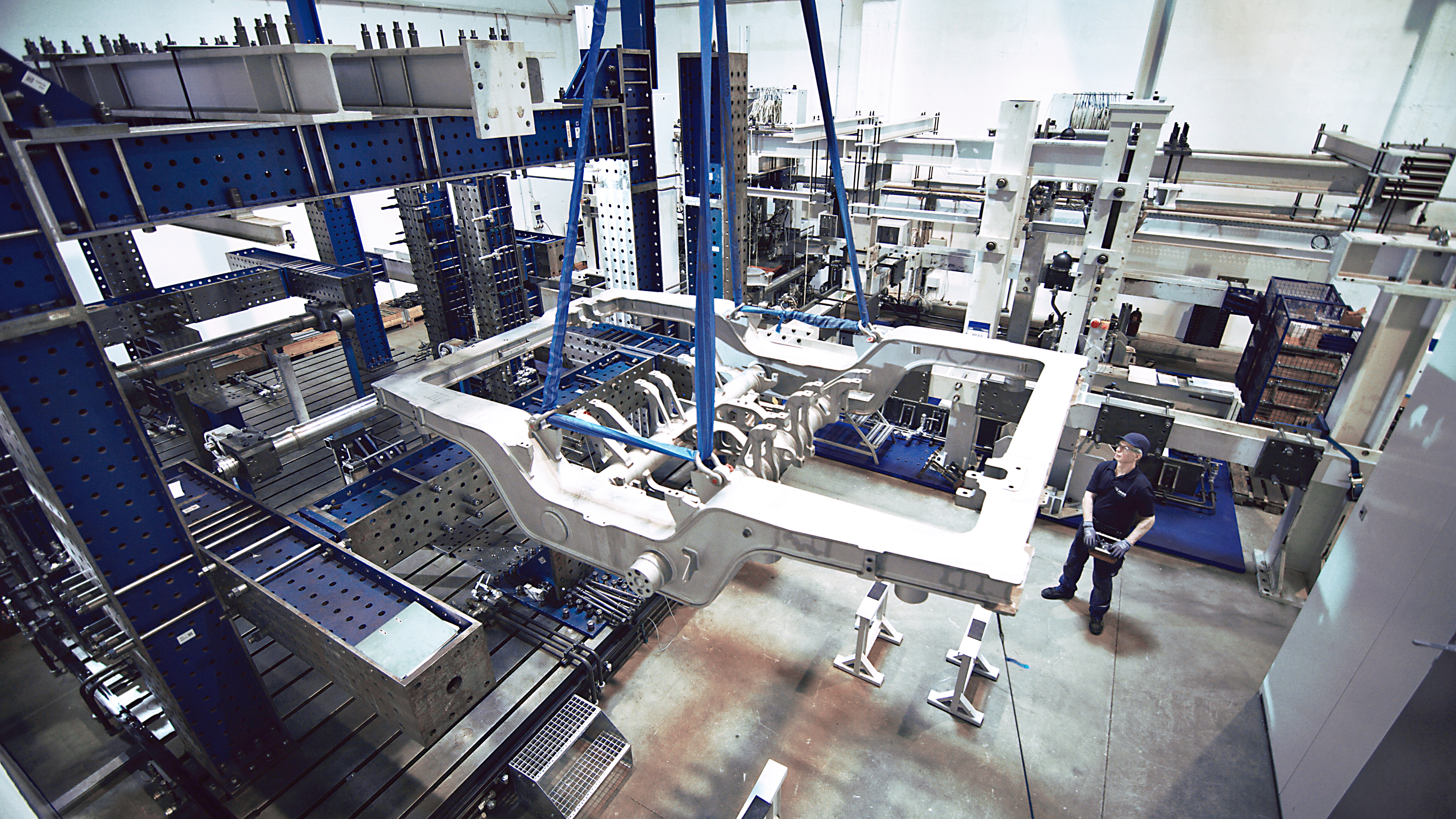

RAILWAY

We are an ISO/IEC 17025 accredited laboratory enabled to test:

- Complete rail car bodies according to EN 12663-1

- Bogies and bogie frames according to EN 13749 for all types of trains (trams, locomotives, freight or passenger trains).

We also perform tests for OEM-specific standards and can carry out design and test plans with your own specific load requirements. We work to verify strength, stability, and durability on full-scale structures and test a large range of substructures and smaller components too (e.g. axle boxes according to EN 12082).

CONSTRUCTION AND CIVIL INFRASTRUCTURE

Applus+ Laboratories has been partnering with the construction industry for the past 100 years. Throughout this trajectory, we have amassed the equipment, accredited laboratories and technical specialists necessary to undertake the mechanical validation of enclosures, construction materials, building systems, structural bearings and waste channels, and grates. In addition, our laboratories have been audited by EOTA-approved bodies, allowing the structural testing of reactive bridge components.

Related services to Structural Testing

News' Carousel

-

24/04/2024 Applus+ RA USA is adding new automotive tests construction materials for various types of siding

-

08/08/2023 Applus+ Laboratories enhances its material testing services for automotive product development ...

-

08/08/2023 Applus+ Laboratories enhances its material testing services for automotive product development ...

-

27/06/2023 Socomore and Applus+ Rescoll sign an agreement to commercialize intumescent paints for the ...

-

11/06/2023 Applus+ acquires Rescoll, a leading laboratory in France

-

02/06/2022 New accreditations for polymer testing at Applus+ Laboratories Barcelona HQ

-

19/05/2022 Applus+ Laboratories and IMA Dresden to exhibit together at Automotive Testing Expo 2022

-

27/05/2021 Applus+ acquires IMA Dresden, a leading testing laboratory in Europe

Applus+ uses first-party and third-party cookies for analytical purposes and to show you personalized advertising based on a profile drawn up based on your browsing habits (eg. visited websites). You can accept all cookies by pressing the "Accept" button or configure or reject their use. Consult our Cookies Policy for more information.

-

Essential cookies

They allow the operation of the website, loading media content and its security. See the cookies we store in our Cookies Policy.

Always active -

Analytics cookies

They allow us to know how you interact with the website, the number of visits in the different sections and to create statistics to improve our business practices. See the cookies we store in our Cookies Policy.

-

Advertising cookies

Based on your behavior on the website (where you click, how long you browse, etc.) we establish parameters and a profile for you to display ads that correspond to your interests. See the cookies we store in our Cookies Policy.