We provide comprehensive testing services for low voltage components as well as high voltage systems that power electric and hybrid vehicles. Learn more about our dedicated capabilities in High Voltage Components, Electric Motors, and Battery Systems testing.

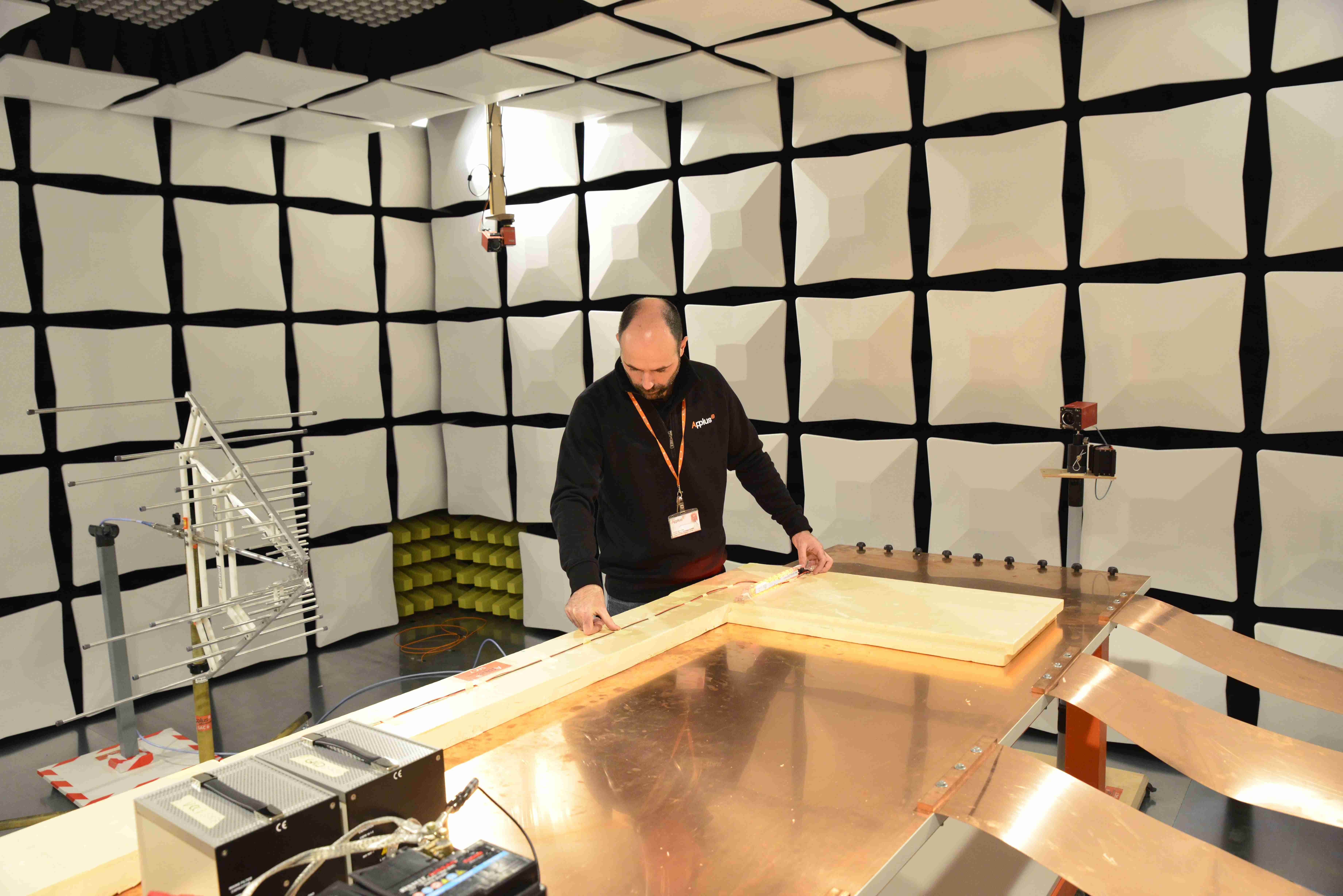

EMC Testing for Automotive Components

We test according to the EMC standards of all automotive OEMs including those that require an specific laboratory recognition or approval like Ford, GM, Stellantis, Jaguar Land Rover, Hyundai, and several major Chinese manufacturers. This ensures that our test results are recognised and accepted by OEMs, as well as for homologation and market access worldwide. Our capabilities include:

- Radiated Emissions (RE) and Radiated Immunity (RI)

- Conducted Emissions (CE) and Conducted Immunity (CI)

- Electrostatic Discharge (ESD)

- Transient Immunity and Emissions

- Magnetic Field Testing

- Bulk Current Injection (BCI)

Key standards and regulations for EMC testing: UNECE Regulation 10, CISPR 25, ISO 11452 series, ISO 7637 series, ISO 10605 and OEM-specific requirements.

Key Facilities and Equipment:

- Semi-anechoic chambers from 1 to 10 m measurements.

- Reverberation chambers

- Shielded rooms

- State-of-the-art instrumentation for emissions and immunity measurements

.2025-12-09-12-19-00.jpg)

More on our capabilities, expertise and global footprint for Automotive EMC Testing for components. We also offer EMC testing for complete vehicles. Learn more about our full vehicle EMC testing services.

Electrical Testing for Automotive Components

We verify the electrical test requirements to ensure the reliability and robustness of automotive components in compliance with international and industry standards. We cover all type of electronic components:

- 12 V & 24 V components (e.g., LV 124 & ISO 16750)

- 48 V components (e.g., LV 148 & ISO 21780)

- High Voltage Components up to 1.5 kVDC or 1.0 kVAC (e.g., LV 123 & ISO 21498)

- Electrical safety testing (UNECE Regulation 100)

- Connectors in motor vehicles (LV 214)

- Short circuit test on electric equipment (AC/DC high current testing up to 25 kA @800 VDC or 30 kA @1,100 VAC)

- Fuses and connectors (determination of derating curves)

Environmental Testing for Automotive Components

We simulate the environmental conditions to test the effect of external influences on electrical and electronic components, ensuring reliability and durability under extreme and real-world conditions. Our capabilities include:

- Temperature & Humidity Cycling

- Thermal Shock

- Corrosion Testing (including SO₂)

- Dewing

- IP Protection Degrees (Dust & Water)

- Icing

- Solar and Xenon Radiation

- Accelerated Aging & Life testing

Key Standards for Environmental Testing: ISO 16750 series, LV 124, LV 148, LV 123, ISO 20653, IEC 60068 series and OEM-specific standards.

Key Facilities and Equipment: Wide range of environmental chambers from small size to walk-in and drive-in chambers, including fast rate climatic chambers.

NVH Testing for Automotive Components

We test your products, components, and assemblies in our vibration and acoustics laboratories to verify their compliance with industry standards for vibration, shock, and acoustic performance. Our services ensure your components meet reliability and durability requirements under real-world mechanical stresses, as well as deliver optimal acoustic quality. Our capabilities include:

- Vibration testing

- Combined vibration, environmental, and acoustic testing

- Mechanical shock testing

- Road spectrum vibration tests (MAST), combinable with walk-in climatic chambers and solar exposure

- Buzz, Squeak, and Rattle (BSR) evaluation

- Acoustic power measurement and characterisation

Key standards for NVH testing: ISO 16750 series, LV 124, IEC 60068 series and OEM-specific standards.

Key facilities and equipment: Our facilities are equipped with multiple electrodynamic shakers (up to 200 kN), including Road Spectrum Simulation (MAST) systems across our global sites. We also feature specialized BSR shakers in silent rooms and anechoic chambers for precise acoustic characterization.

Why Applus+ Laboratories?

With our global network of accredited laboratories, state-of-the-art facilities, and recognition from major international OEMs, Applus+ Laboratories is your trusted partner for the validation of automotive electrical and electronic components. Our comprehensive portfolio covers EMC, electrical, environmental, and NVH testing, ensuring your products meet the highest standards for quality, safety, and market access worldwide.

Contact us to discuss your testing needs and discover how we can help accelerate your product’s path to product validation/homologation and global markets.