END-TO-END MATERIALS TESTING SERVICES

Applus+ is an strategic supplier of materials testing services for the aerospace industry. We provide an end-to-end testing service, covering a wide range of materials characterization tests combined with sample manufacturing and machining capabilities.

MECHANICAL TESTING

- Tensile

- Compression

- Bearing

- Shear

- Flexural

- Drum peel

- High-cycle fatigue

- Low-cycle fatigue

- Crack propagation/crack growth

- Creep

- High strain rate

- Temperatures from -196ºC to +1200ºC

SAMPLE PREPARATION

- Composite samples manufacturing

- Test samples machining and preparation

- Tabs bonding

- Low-stress grinding and polishing

- Samples conditioning

- Laser sample marking system: guarantees full traceability of each sample

PHYSICAL-CHEMICAL TESTING

- Thermal analysis

- Physical analysis

- Rheological analysis

- Chemical analysis

METALLURGY & FAILURE ANALYSIS

- Metallographic examinations

- Grain size

- Hardness

- Behavior in environmental conditions / corrosion

- Surface treatment testing

- Failure analysis

- Chemical analysis (OES)

NON-DESTRUCTIVE TESTING

- Manual & automated NDT

- Techniques: VT, PT, MT, UT & ET

A network of fully-accredited laboratories

Our network of materials testing laboratories in Europe and Asia are Nadcap accredited for metallic and non metallic materials testing. Applus+ materials laboratories is also approved by the leading aircraft manufacturers and their Tier 1 suppliers.

ISO / IEC 17025 Accreditation

- Composites Testing

- Metals & Alloys Testing

- Polymers

- Coating

NADCAP Accreditation

- Materials Testing Laboratory

- Non Metallic Materials Testing

- Non-destructive Testing

Customer Approvals

- Airbus

- Airbus Helicopters

- Airbus Space & Defense

- Embraer

- Comac

- Safran

- Honeywell

- Avic

- Aubert&Duval

- Areva

Customer support along the entire value chain

- Material characterization: manufacturing & testing

- Raw material-incoming inspection activities

- Control process testing

- First-part qualification and witness testing

- Failure analysis for in-service support

- R&D support

- MicroVu laser control system: 100% control of our machining operations and the production of a complete report.

Digital solutions for materials testing, CAE simulation and materials data-management

- TestPaks®: select material models, order tests online, convert data parameters and receive CAE-ready files

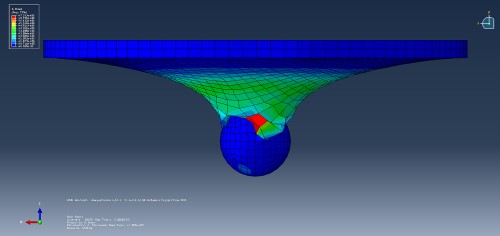

- CAETestBench®: validate your simulation against the results of laboratory-testing on standardized parts

- Matereality®: Software and infrastructure for material data management

Specialist in aero-engines materials testing

- Fully equipped to work at high temperatures to support aero engine testing needs

- End to end capabilities: samples extraction, machining, dimensional check and testing

- Nadcap MTL accreditation for testing (A), (B), (KR), (O), (P), (XE), (Y) and machining (Z), (Z2)

.jpg)

.jpg)