Introducing CAETestBench

CAETestBench is a process where we validate your simulation against a physical part that has been created and tested using a rigid protocol, which can be accurately replicated in your solver. With this, it is possible to probe the accuracy of the simulation to quantify its ability to replicate real-life simulations. The deformations range from simple tensile modes to more complex, multi-axial modes, impact, and failure.

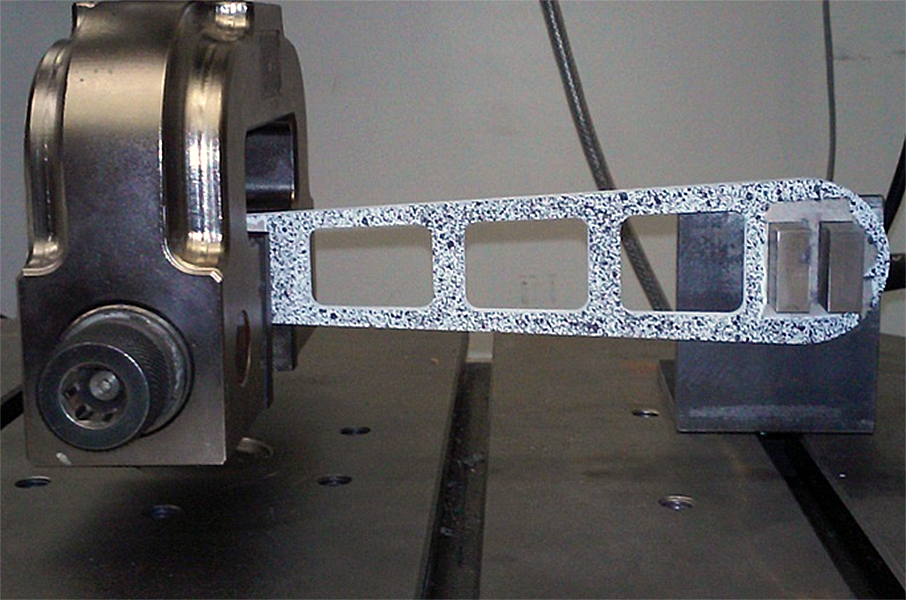

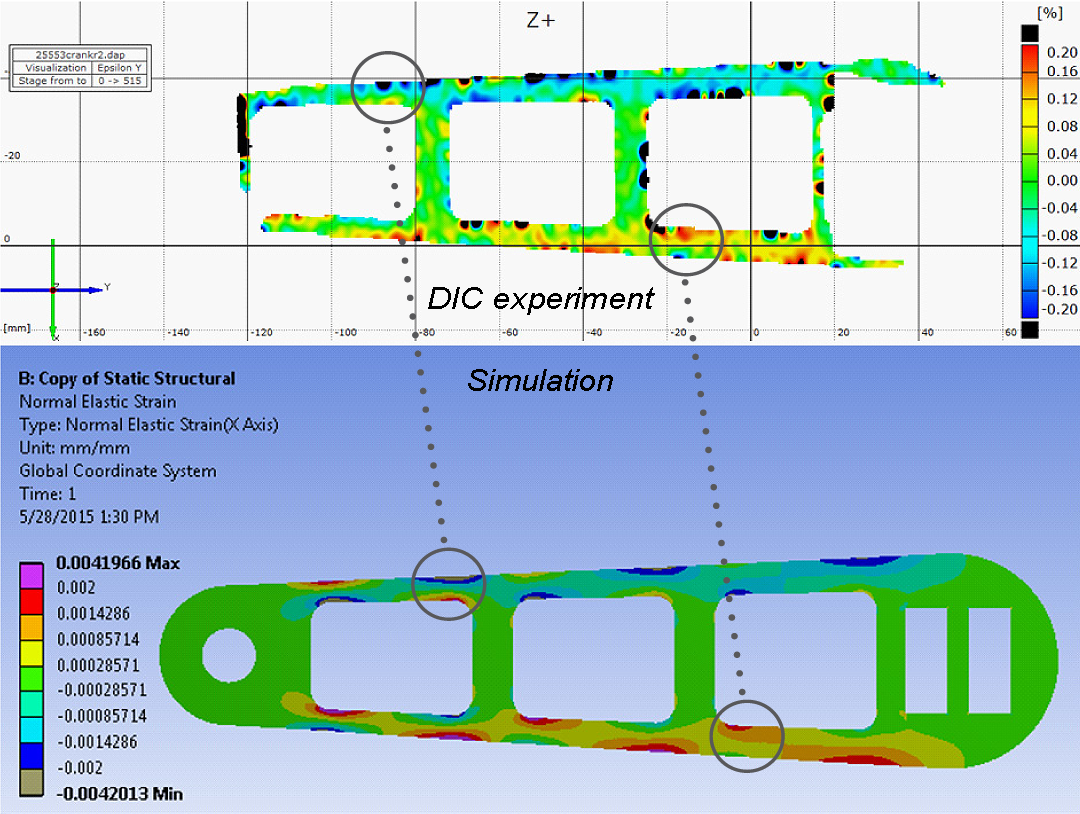

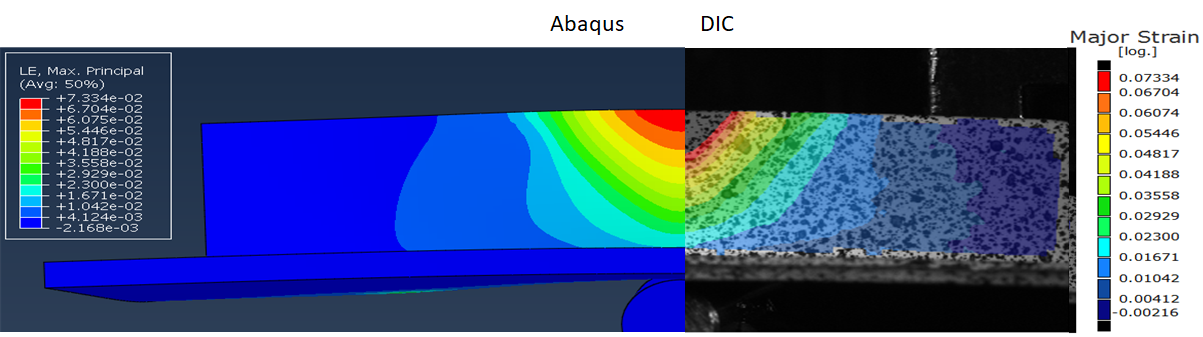

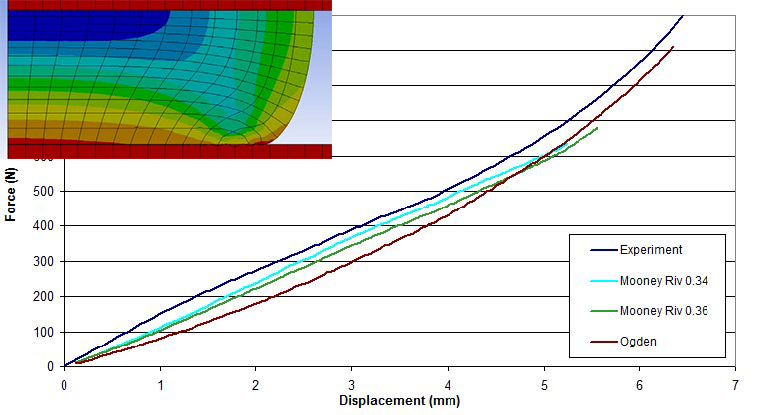

A CAETestBench validation quantifies the effect of the inputs of a simulation, using carefully controlled physical tests that can be simulated with precision. The tests utilize standardized parts containing geometric features that probe the accuracy of the simulation. An objective measure of accuracy can be obtained by comparing experimental strain fields obtained by digital image correlation (DIC) against the simulation.

Available validations:

- 3D Printing Validations

With 3D printing and additive manufacturing, manufacturing designs previously thought difficult to produce can now be generated quickly, efficiently and without tooling. Additive manufacturing coupled with topology optimization allows the design and analysis loops and manufacturing iterations to be reduced significantly or even eliminated. 3D printing validations prepare the simulation for these steps by confirming that the simulation accurately represents the material and the real-life situation.

Traditionally, the design process often involved much iteration between the designer and the analyst, where the designer would submit a design to the analyst, and then the analyst completed his or her analysis and sent recommendations back to the designer. The process was repeated until a valid design met the analysis criteria. The design was then handed to the manufacturing team which then may have had additional constraints or concerns, leading to more iterations. - Plastics Validation

Finite element analysis of plastics contains assumptions and uncertainties that can affect simulation accuracy. It is useful to quantify these effects prior to using simulation for real-life applications. A mid-stage validation uses a controlled physical test on a standardized part to compare results from simulation to physical experiment. These validations do not use real-life parts but carefully designed geometries that probe the accuracy of the simulation; the geometries themselves can be tested with boundary conditions that can be simulated correctly. In this validation, a quasi-static three-point bending experiment of a standardized parallel ribbed plate is performed and simulated. A comparison of the strain fields resulting from the complex stress state on the face of the ribs obtained by digital image correlation (DIC) vs. simulation is used to quantify the simulation's fidelity. - Rubber Hyperelasticity Validation

Hyperelastic material models are complex in nature requiring stress-strain properties in uniaxial, biaxial and shear modes. The data needs to be self-consistent in order to fit the commonly used material models. Choosing models and fitting this data to these equations adds additional uncertainty to the process. We provide a validation mechanism where, using a standard validation experiment one can compare results from a simulation and a physical test to obtain a quantified measure of simulation quality. Validated models can be used with greater confidence in the design of real-life components. - Crash Validation

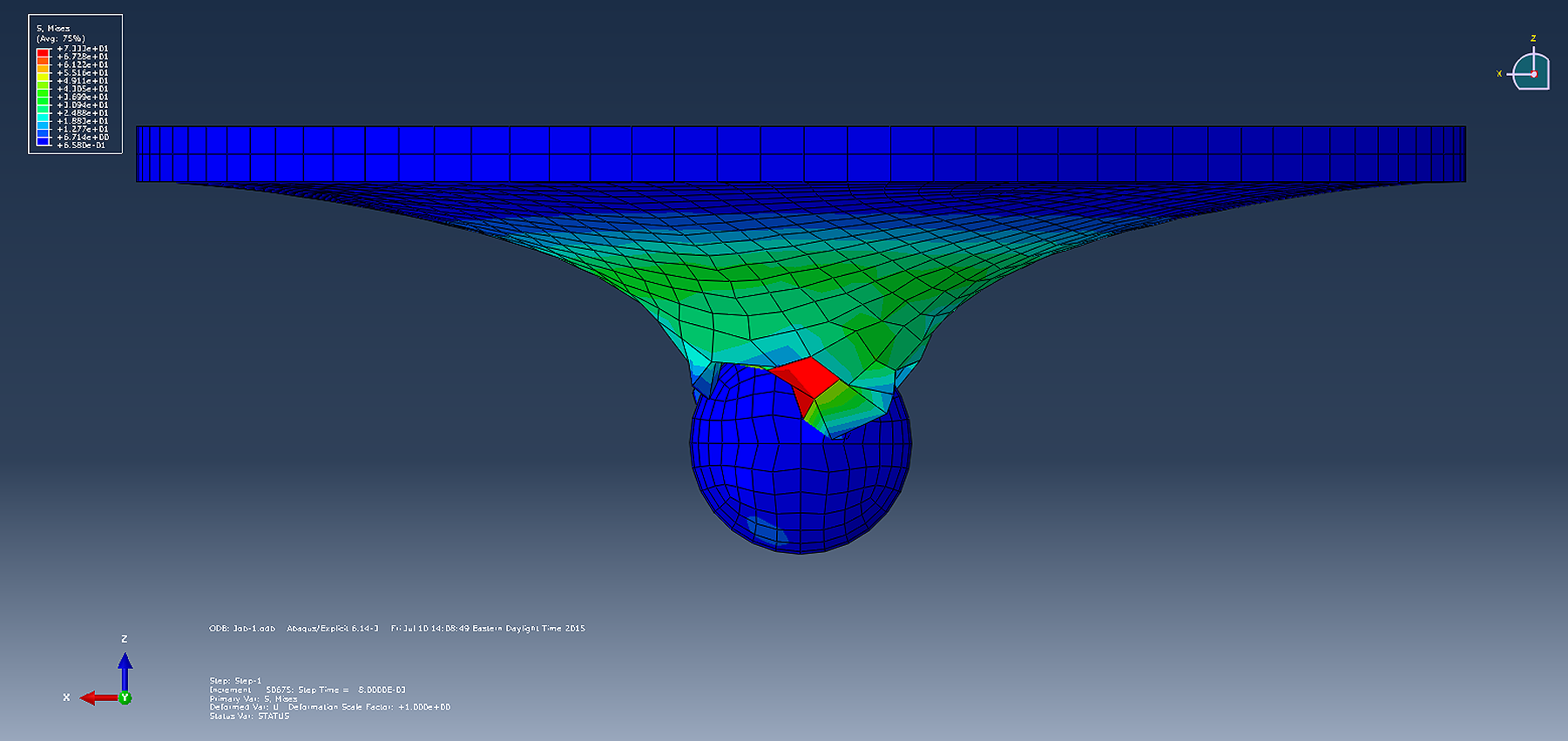

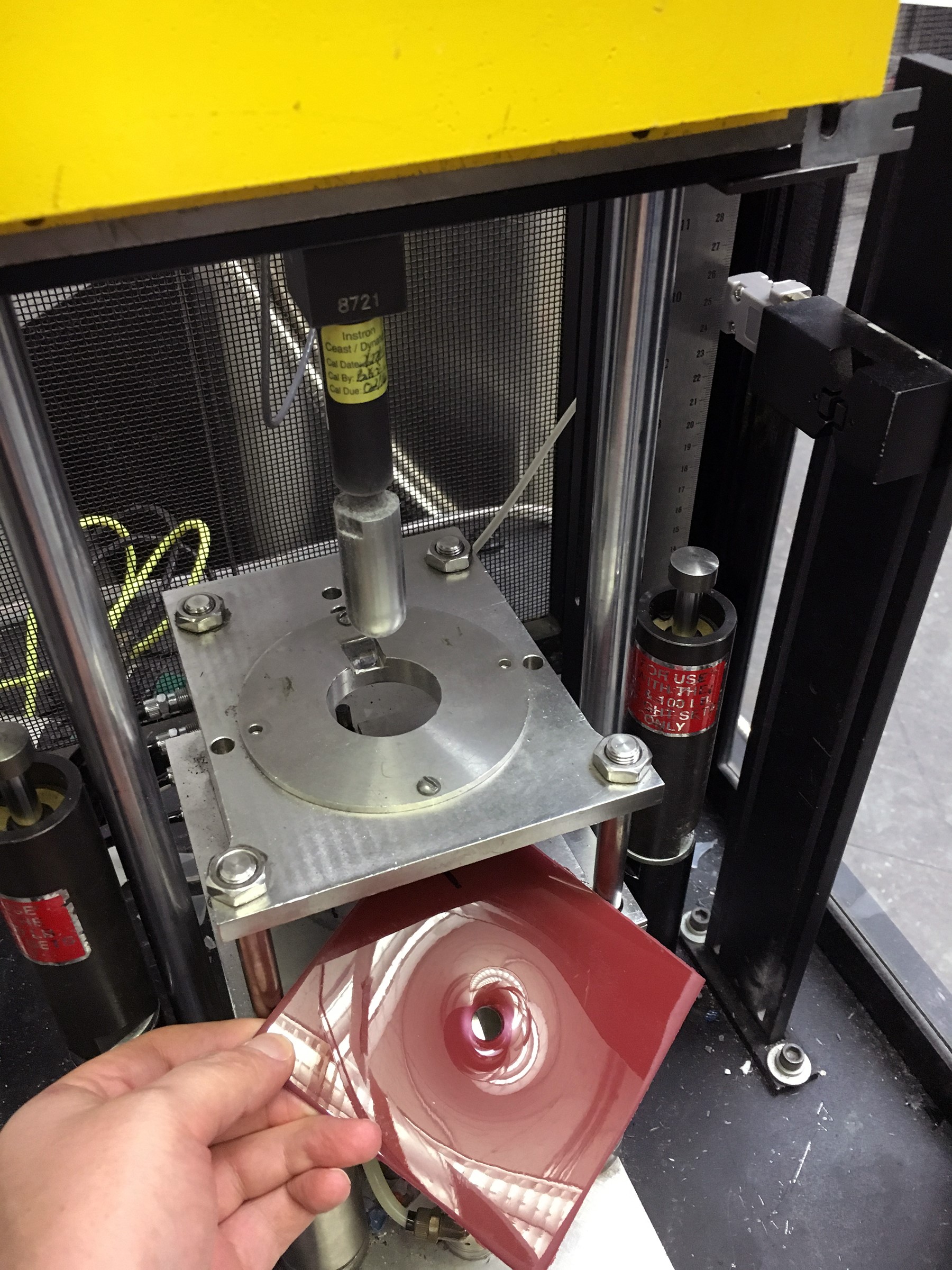

Quantifying simulation accuracy before running crash simulations could be a helpful confidence building measure. This validation utilizes a dynamic dart impact experiment to probe the multi-axial deformation of the material until failure. The validation provides a mechanism to verify material models, element size and selection and solver settings and can be used for isotropic materials that include options for rate dependency and failure.