Medical Devices & Healthcare

Testing Services for Medical Devices

One-Stop-Shop Testing for Medical Devices

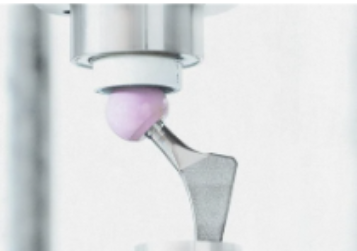

Biomechanical Testing

Biomechanical Testing

- Medical Material and Coating Testing

- Wear Testing

- Corrosion Testing

- Static and Dynamic Testing

- Metallography– Microstructure Analysis

- Damage Analysis

- Surface Testing

Chemical Testing

Chemical Testing

Packaging Testing

Packaging Testing

- Real-time and Accelerated Aging

- Temperature Validation

- Transit Test Simulation

- Sterile Barrier

- Packaging Validation for Medical Devices