Applus+ NRAY

Applus+ NRAY is a leading provider of neutron radiography services. Its non-destructive testing examinations are fit to meet the challenging demands of a wide range of international and global clients from aerospace, defence, space, manufacturing, and research & development.

The company was founded in 1994 in Dundas (Ontario, Canada) and a second facility was established in Raleigh (North Carolina, USA) in 2008. In 2014, it joined the Applus+ group. NRAY is a division of the Applus+ Laboratories group.

Applus+ NRAY Accreditations

Applus+ NRAY is certified to AS9100D with ISO 9001:2015 at our Canadian sites for Neutron Radiographic imaging and testing by NSF-ISR.

Applus+ NRAY has approvals from many aerospace organisations. The company routinely conducts work for both civilian and military purposes to these standards.

Applus+ NRAY Services

Applus+ NRAY Services performs neutron radiography, a highly advanced Non-Destructive Testing (NDT) method with unique applications. Neutron radiography ensures the detection of ceramic residual cores in aircraft turbine components.

These are some of the specialised services Applus+ NRAY provides to meet the challenging demands of key industry players.

Neutron radiography

Applus+ NRAY performs neutron radiography, a specialised NDT method that enables inspections that go beyond X-ray imaging. Nuclear reactors provide the intense neutron sources required to visualise objects based on their interactions with neutrons, which provides a new range of possibilities compared to traditional NDT methods.

Neutron radiography training and consulting

Applus+ NRAY provides formal training courses and consulting based on client requirements. Training courses are scheduled on demand to fulfil customer and end-customer requirements for neutron radiography users and professionals. Training can be conducted out of our Canadian or US facility, or at alternate locations.

For new neutron radiography users and those establishing an imaging system, Applus+ NRAY provides equipment and consulting.

Turbine Engine Parts

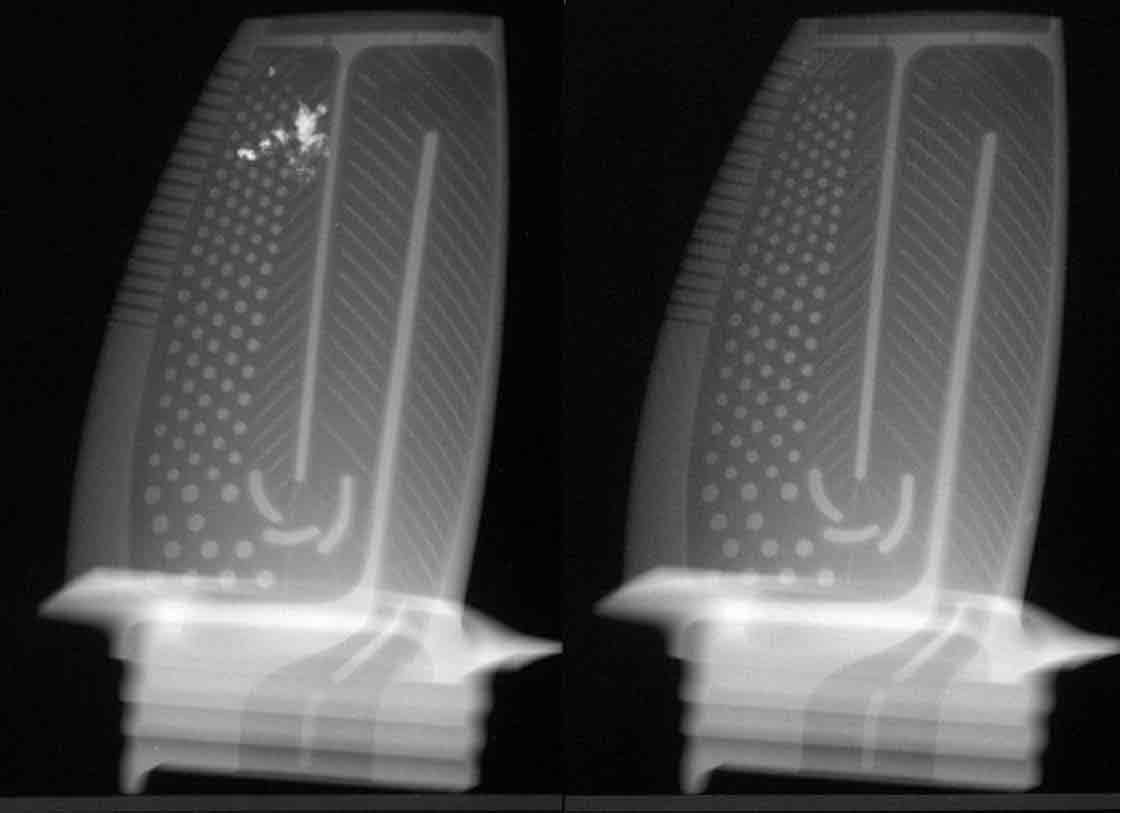

Applus+ NRAY performs routine inspections on turbine blades and vane segments, using neutron imaging to detect residual cores during the manufacturing process. Additionally, it examines aircraft fuel nozzles to identify carbon build-up accumulated during use and assesses composite fan blades for manufacturing defects, offering an alternative to X-ray CT.

Contrast Enhancement

Applus+ NRAY has tagged millions of turbine blades for jet engines. Tagging is a pre-treatment process that makes any core remaining in metal castings visible with neutron radiography. This is accomplished by adding a strong neutron absorber (gadolinium) to any core remaining in the turbine blades or vane segments to make them more visible to neutrons. Tagging can be utilised for other applications as well when material properties prevent direct visualisation, greatly expanding the contrast enhancement neutron radiography method.

Neutron imaging supplies

Applus+ NRAY, distributes and re-sells neutron radiography and imaging supplies, equipment and materials.

These neutron imaging supplies include image quality indicators built to ASTM standards, ASTM devices, and conversion screens which are used by neutron radiography facilities around the globe.