LARGE AND VERSATILE FACILITIES TO TEST THE STRUCTURAL INTEGRITY OF WHOLE TESTING PYRAMID

- Supporting tests throughout the whole testing pyramid, from coupons to full-scale testing.

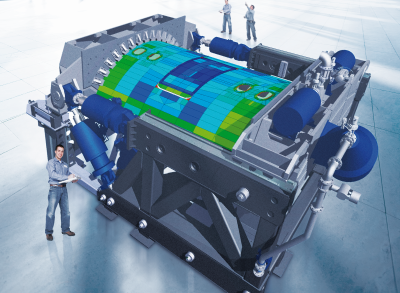

- Uniaxial and multiaxial high load specialists, static and fatigue tests (up to 15 MN)

- Testing under controlled conditions, from cryogenic to high temperatures

- Experience testing complete aircrafts, landing gear systems, tail units, fuselage, structures and wings, engines, aircraft interior.

STATE-OF-THE-ART TECHNOLOGY FOR DATA ACQUISITION AND TEST MONITORING

- Instrumentation with numerous data acquisition channels

- Advanced metrological equipment and digital image correlation (DIC)

- Impact equipment to induce controlled structural damage

- Online tools to test remote monitoring and data post-processing (eTesting)

- NDT tear-down activities

NUMERICAL SIMULATION AND STRENGTH EVALUATION

Engineering services throughout the entire development phase as well as during the use of a product, taking the economic requirements for shorter production development times and innovative and high-quality design with better material efficiency and weight-optimised structures into account for optimal flow of forces.

FEM ANALYSIS: Experienced calculation engineers from the fields of statics, operational strength and dynamics are on hand to optimise your product by scaling its mass and form, on the basis of FE analysis. We determine stresses and deformations, examine the stability behaviour, obtain static, operational and permanent strength verifications, evaluate natural modes and resonances, and analyse and assess damage.

STRENGHT ANALYSIS: Analyse the stress and reliability of components and structures using the finite elements method and carry out strength tests. We make statements about the safety of designs, in the form of static strength verification, operational strength verification and fatigue strength verification

Long term experience in standardized and customized aerospace testing

- Broad experience, with more than 50 years background in Aerospace Testing

- Always prepared to setup customer specified testing projects

- Always prepared to develop customer specific testing methods or specifications

- Always open to manufacture and operate customer-defined testing equipment on customers premises or in our laboratories

Ability to meet the strict delivery times of aerospace programmes

- Robust organizational and flexible workforce capabilities

- Project management expertise in international testing programmes

- Test tooling: In-house design, simulation and manufacturing to requested load boundary conditions

A reputable lab, qualified by the major aerospace, helicopter and aero-engine manufacturers

- Global leader in large carbon-fibre panels, with over 50 wing panels tested

- Certification testing campaigns for aero engine parts

- Complex testing campaigns for different helicopter programmes

- Expertise in tests with complex mechanical loads (HTP, VTP, etc.)

A testing partner for R&D and certification programmes

- A trusted lab with experienced teams in certification testing helicopter programmes

- We collaborate and support research and technology programmes through our first-class facilities

- Active participants in government-funded research programmes