DEMONSTRATE Project

Demonstration of the structural integrity of new airframes.

Started: 2021

Completion: 2023

Participants: Leader: Applus+ Laboratories, ATHENA-RC

Funding: This project has received funding from Clean Sky 2 Joint Undertaking (JU) under grant agreement no. 101007881. The JU receives support from the European Union's Horizon 2020 research and innovation programme and Clean Sky 2 members other than the Union.

The DEMONSTRATE R&D project is part of the Clean Sky research programme, which focuses on developing cutting-edge technologies to optimise the environmental performance of aircraft and air transport.

DEMONSTRATE is part of Activity C (Eco-Design) of Clean Sky's AIRFRAME Integrated Technology Demonstrator.

Objective

The objective of the Demonstrate project is to evaluate the structural resistance of two new airframe designs; one in Al-Li alloy and one in thermoplastic.

The Demonstrate project is divided into four specific yet complementary research areas:

- Development of a new virtual test methodology to evaluate the influence of various boundary and loading conditions on curved panels representative of the conditions airframes are subjected to when under flight conditions;

- Development of a novel test bench concept, which is easily adaptable to different geometries, and which allows the required boundary/load conditions to be introduced;

- Study of new metrological techniques to monitor panel deformation and capture damage during the test;

- Development and application of an advanced simulation methodology specific to the materials used in this project (Al-Li alloy and thermoplastic).

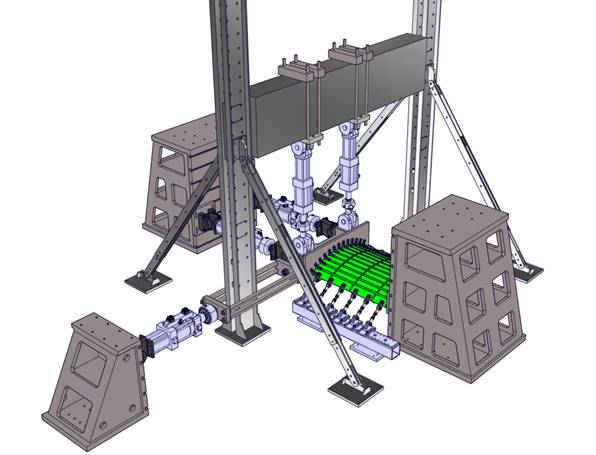

Versatile Test Bench Concept

In this project Applus+ Laboratories proposes to develop a test bench for curved fuselage panels that will guarantee:

- The adequate introduction of axial, bending, torsional and shear loads

- The simulation of internal pressure changes that result from cabin pressurisation and depressurisation

The Demonstrate project test bench will be suitable for testing a wide variety of large curved panels, of different lengths and curvatures with different load configurations and boundary conditions too.

Due to the variability of curvature radii and beam geometry of the panels, it will be necessary to design a test rig that allows the modularity of its components to be easily adapted to each configuration to ensure full structural certification.

The test rig proposed by the Demonstrate consortium requires only one curved panel segment instead of a complete cylindrical section of the fuselage, allowing new structural concepts and new materials to be validated at a lower cost.

A Robust Methodology for Monitoring the Component, Test Bench and Boundary Conditions

The accuracy of the FEM models used to perform virtual tests can be evaluated by performing laboratory tests, then contrasting the information obtained with the results of the virtual tests.

To this end, this project will implement the Absolute Accurate methodology. This is an experimental approach developed by Applus+ Laboratories that aims to provide a more robust way of identifying the boundary conditions of the tests performed by extending the instrumentation beyond the sample and monitoring the test bench.

Specific Digital Tools to Compare Test Results in Laboratories or Simulations

Innovative tools developed by Applus+ Laboratories will be used to improve the calibration and validation of FEM models.

These software solutions provide a digital infrastructure to facilitate the comparison of experimental test results and simulations, the creation of material charts used in the simulation software and the validation of the simulation model.

Improving the Quality of Results: Agility and Precision

As the project aims to improve the quality of results, Digital Image Correlation (DIC) technology will be applied. This allows a faster and more accurate measurement of the deformation field of a structure.

Real-Time Deformation Field Monitoring

The monitoring of the deformation field will be carried out in real-time thanks to the optimised algorithms of Digital Image Correlation (DIC).

New methods will also be applied to improve the detection of crack/delamination initiation and propagation, using:

- Acoustic camera and non-contact metrology for rapid detection of indications that may signal delamination or crack initiation.

- Non-linear stimulated IR thermography

Time Optimisation in the Detection and Monitoring of Damage During Testing

To perform the standard non-destructive inspection techniques used to monitor crack initiation, crack evolution (in metallic structures) and damage growth (in composites), the test needs to be stopped, and these inspections have a significant impact on test execution time.

The test campaign also has various different requirements as a result of the variety in:

- loads: static, fatigue

- materials: metal, composites

- state of damage: initiation or propagation

- level of damage characterisation: identification vs. quantification only

To satisfy all these different requirements and bypass the delays that would be caused if using standard non-destructive inspection techniques, various damage monitoring techniques will be applied which don’t require contact:

- Detection of debonding and damage growth through the use of an acoustic camera

- Thermography based methods for the detection of damage initiation and propagation in composite materials

- Acoustic Emission technique for damage identification

- Local detection of debonding and damage growth by Phased Array Ultrasonic

- Silver coating paint for local control of crack initiation and propagation on metal panels

For more information on the project, see: https://www.horizon-demonstrate.eu/