In order to power e-motors and improve its performance, voltage is growing in several key components of electric and hybrid vehicles. Validation of this type of equipment requires specific laboratory equipment and technical expertise to test their EMC, electrical and environmental performance. As a leading laboratory in automotive components testing in Europe, Applus+ Laboratories is ready to test nearly all types of HV components.

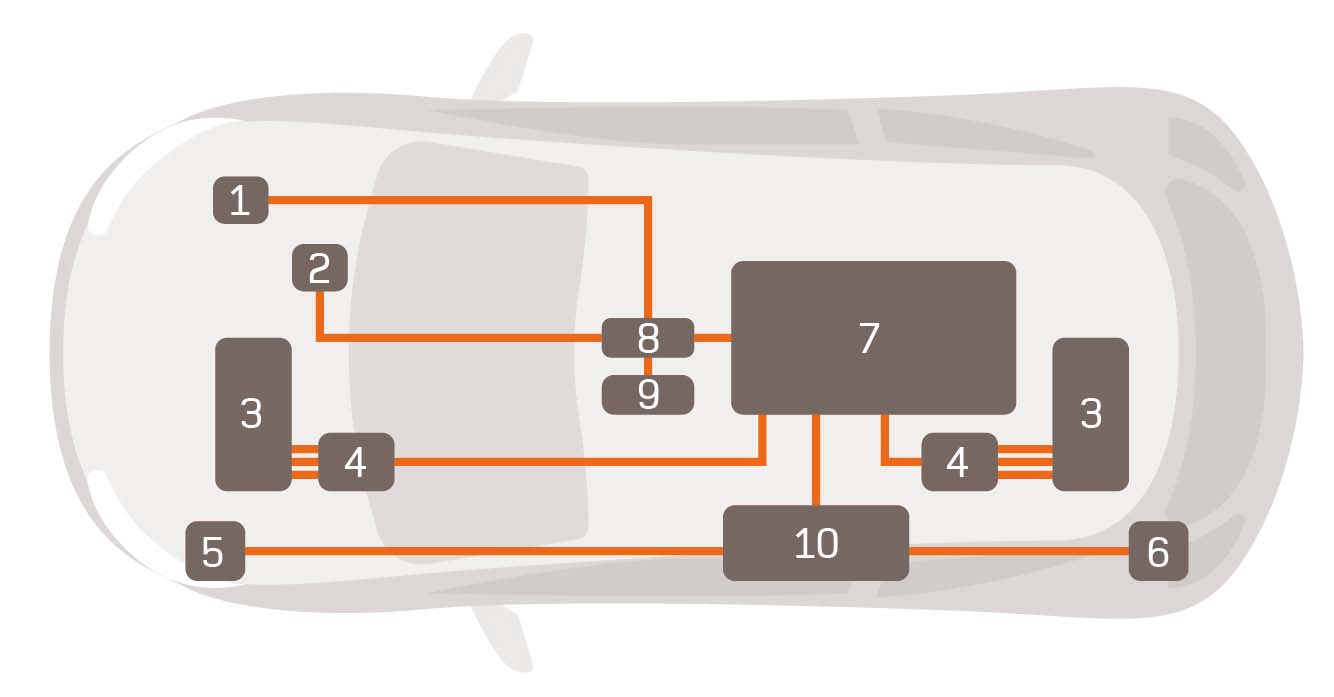

Scope of HV Components and Systems tested

Our laboratories have the technical capabilities and experience testing the following HV systems

- HVAC Compressor

- Electrical Heater

- E-Motor

- Inverter

- HV Pump (Cooling)

- Charging Socket

- HV Battery Packs & Battery Management System

- HV Power Distribuition

- DC/DC Converter

- On-Board Charger

- Fuses, Contactors

EMC Testing of HV Components

EMC Test Stardards for High Voltage Components

- International standards: ISO 7637-4, CISPR 25, ISO 11452-X

- Bespoke manufacturer requirements: BMW GS95002-3, Ford FMC1280, Mercedes-Benz MBN10284-3, Nissan 28401NDS02, PSA B21 7112, Renault 36-00-811, Volvo 31857169, among others

- UNECE Regulation 10

EMC Testing Service overview

- Emissions testing: DC to 40GHz capability including FFT capabilities

- Immunity testing:

- DC to 18GHz capability (up to 200 V/m, up to 600 V/m for radar modulations)

- Amplifiers up to 5kW

- Electric & Magnetic low frequency field testing

- EMF measurements

- ESD testing to 30kV

Electrical & Environmental Testing of HV Components

Environmental and Electrical Test Stardards for HV Components

- International Standards: ISO 21498-2, LV 123

- Bespoke manufacturer requirements: VW80300, BMW GS95023, MBN LV 123, PSA B7112

Environmental & Electrical Testing Service Overview

Assess the safety and reliability of HV components in different voltage and temperature ranges.

- Climatic Chambers for HV Components. Size: 1.5 - 2 m3; Thermal gradient: 10 to 12 K/min; Temperature range: from -90 ºC to 180 ºC; Heat compensation: >10 kW (from -40 ºC to 125 ºC) for dissipative components like air heaters

- Electrical connection for DUT: Electrical connection of 300 kW. 6 power outlets of 22 kW per climatic chamber

- Coldwater circuit for feeding customer chillers (if needed)

- Electrical Testing with the most stringent requirements.

- Voltage ripples up to 150kHz and >32Vpp

- HV load dump pulse with 250V/ms rate

- HV load dump with rapid change rate of 3000V/ms

- Short Circuit Tests up to 30kA

Complete validation of HV components

Applus+ Laboratories is able to perform complete validation plans for HV components, including EMC, Electrical, environmental and vibration testing. Our laboratories are equipped with all the auxiliary equipment needed for testing at high voltages, and remote monitoring and assistance systems too. Our customers can take part in the setup and monitor the tests from their own offices, eliminating the costs of transporting personnel and equipment.

Support Equipment

Our laboratories are equipped with state-of-the-art equipment required to test components operating at high voltage.

- HV Power Supply

- HV/LV Electronic Load

- LV Electronic Load

- 3-phase Power Supply

- HV 4 Quadrant Amplifier System

- HV Input Filters

- HV Shielded LISN

- Chiller: water/oil cooling