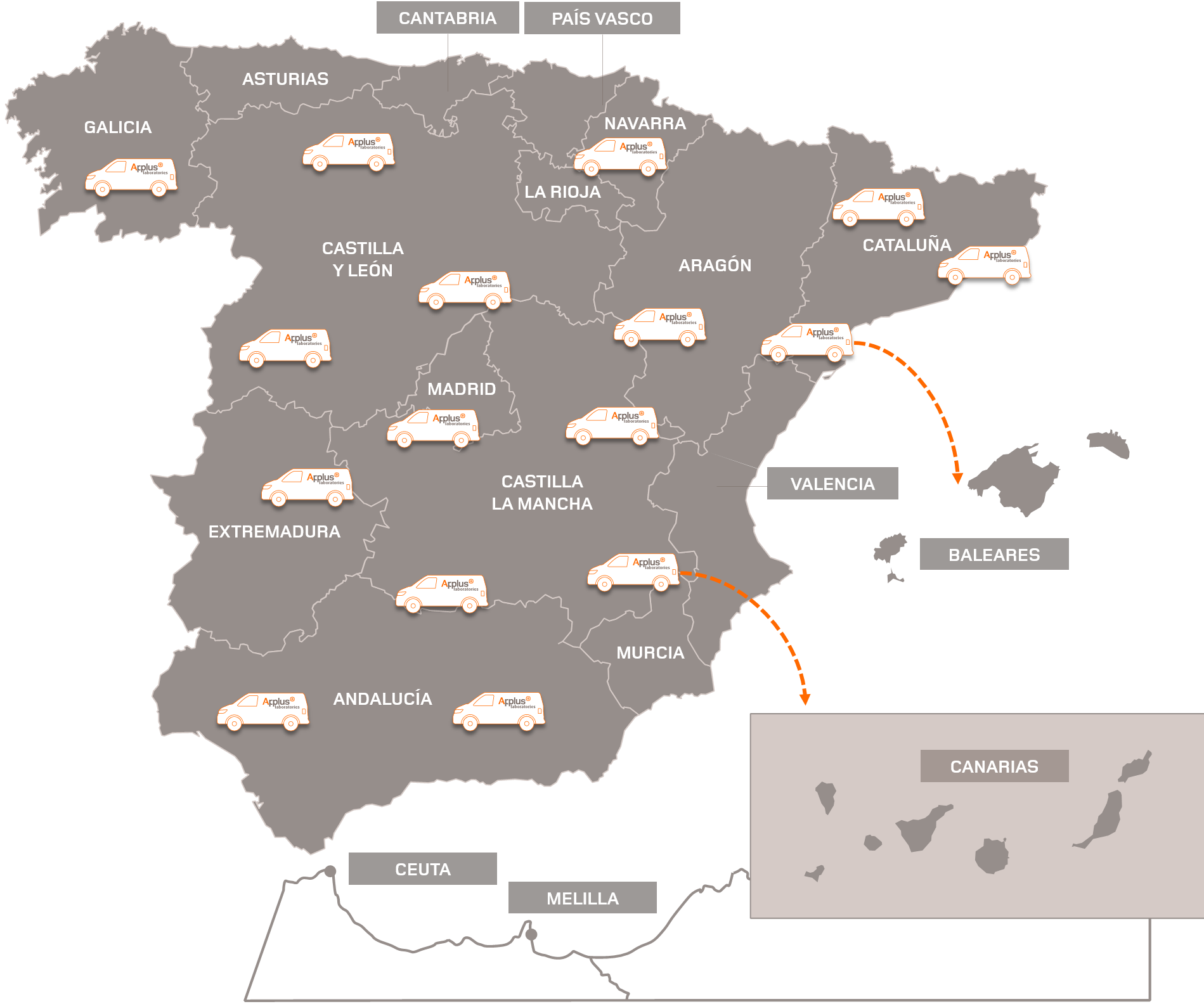

Mobile Calibration Units (UNIMOC)

Our network of 16 accredited Mobile Units qualified of performing calibrations accredited by ENAC with accreditation No. 25 / LC10.016 and No. 25 / LC10.151 is spread throughout the Iberian Peninsula. These units are located at strategic points (see the map) to ensure they cover every location, including the Balearic and Canary Islands. This calibration is performed with the same guarantees as in a permanent laboratory, but with the peculiarity that it is the technician who travels to the customer's facilities with the calibration standards installed in the mobile unit. This is a solution adapted to the needs of large, multi-site companies who have lots of measuring equipment that needs to be continuously available 24 hours a day.

Specialists in different sectors

We currently work with companies in various sectors, for example:

- Automotive After-Sales workshops, providing services to the major brands in the Automotive sector

- Renewable energy plant maintenance

- Railway maintenance

- Helicopter maintenance

Why on-site calibration?

There are several reasons for calibrating equipment at the customer's premises:

- Equipment characteristics: any instrument that is too large to transport (e.g. testing machines, workshop presses, brake testers, thermographic cameras) or that may suffer misalignments due to vibrations suffered during transportation (e.g. analytical or precision balances) should be calibrated on-site.

- Calibration location: Calibrating certain instruments at a location other than the usual site may affect the calibration status. Different conditions in temperature, humidity, atmospheric pressure, local gravity and so on can affect the equipment. and if not taken into account later in the use of the equipment, can lead to large errors in subsequent measurements, so it is advisable to perform the calibration at the same location as the usual use.

- Production requirements: This is one of the main reasons for on-site calibration, as it avoids shipments of measuring instruments to the laboratory and downtime in which the calibrated equipment is no longer available to the customer and therefore generates production delays. In this way, it is the laboratory that adapts to the customer's production needs by performing the calibration on-site and minimizing the impact on its daily work.

The on-site calibration service is vital for all types of companies, both for those that are integrated by a large number of instruments and heavy machinery, as well as those that, due to production, size or ranges, cannot send their equipment to the laboratory.

We offer on-site services in the following areas:

- Temperature calibration

- Calibration of weighing instruments

- Dimensional calibration

- Electrical calibration

- Force calibration

- Torque calibration

- Pressure calibration